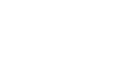

In our previous two blogs we looked at Milestone 1 of our sustainability journey which was about making a commitment to sustainability and Milestone 2 which was about embedding sustainability into the internal operations of your business to give initiatives the greatest chance of success. We talked about establishing a baseline, setting up systems for ongoing monitoring of resource use, and assessing internal operations to identify opportunities to reduce energy, carbon and water use and also waste. All within a frame of continual improvement.

In this blog we look at Milestone 3 – Circular Supply Chains. It is here that you will begin to look beyond the physical boundaries of your business and work with your suppliers and customers to identify wider opportunities for improvement. This milestone involves ‘circular’ thinking – we’re we move away from linear supply chains (the take, make, dispose model ) towards analysing all products and by-products and look towards ‘closing the loop’ and, ultimately, zero waste.

Map your supply chain

The first step in this Milestone is to gain a good understanding of your supply chain by creating a supply chain map. A supply chain map will show the path that major supplies take from raw materials to manufacturers to consumers and end of life. In doing this, you can identify possible areas of risk and where they might occur in the chain.

Examples of risks might include

- changing customer expectations,

- brand reputation,

- lack of appeal to ethical investors,

- animal welfare issues,

- waste and packaging,

- pollution/emission hotspots or

- non-renewable resource consumption.

Developing a map will help visualise your supply chain and identify those areas that have the biggest room for improvement and where change could have the biggest leverage.

Sustainable procurement

Probably the most important aspect of this milestone is to engage strategically with suppliers and customers to work together to achieve positive sustainability outcomes. The possibilities are wide and varied. During this stage you may choose to work on:

- Developing a green and ethical procurement procedure or policy,

- Developing a process for evaluating suppliers,

- Encouraging suppliers to assess their own sustainability performance,

- Developing a framework for collaboration across the supply chain e.g. supplier/customer roundtables

- Investing in research to identify environmental hot spots across the supply chain.

During this step you might work with your customers or suppliers to source or develop more environmentally friendly packaging; there may be an opportunity to improve logistics around the distribution of a product which might reduce fuel use or perhaps even co-investment in a container washing station so that containers can be returned and reused; or you might look more at product stewardship and set up a return or recycle scheme for your brand of product. The opportunities may be simple and quick to implement or be part of a longer term innovative, cutting edge project. Either way, nothing but good can come out of engaging across your supply chain and discussing what challenges there may be and having many heads work on improvements to a system. The possibilities are endless.

To find out more, view our free training video which explains further about the five steps towards improving business sustainability and how you can take them within your workplace.

You can also book in a free 20 minute consultation to discuss how your organisation can achieve its sustainability goals more quickly and efficiently.